Reservoir Tank Breathers & Covers

Zinga offers a selection of reservoir accessories designed to streamline maintenance and help keep your hydraulic systems operating effectively. Products include reservoir breathers, fluid level gauges and reservoir covers.

Reservoir Breathers

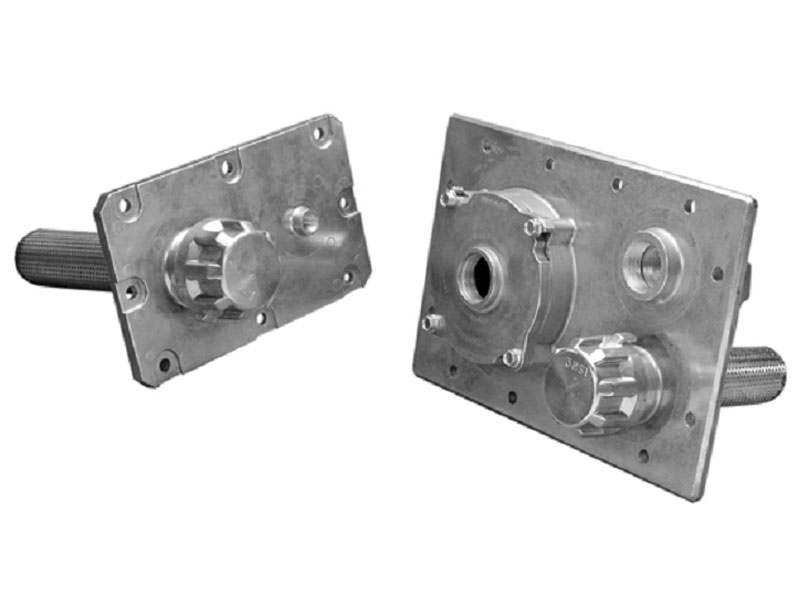

Reservoir Covers

Pressure Gauges

Sight Level Gauges

SG Series

Indicators