Spin-On Filter Heads

Spin-on filter heads are key components to help maintain hydraulic system efficiency while protecting your equipment from wear and tear. The hydraulic filter heads simplify the filtration process. This allows for secure and quick installation while keeping the hydraulic oil contaminant-free. At Zinga, we’re proud to offer these spin-on filter assemblies, and we ensure they deliver consistent performance under demanding conditions.

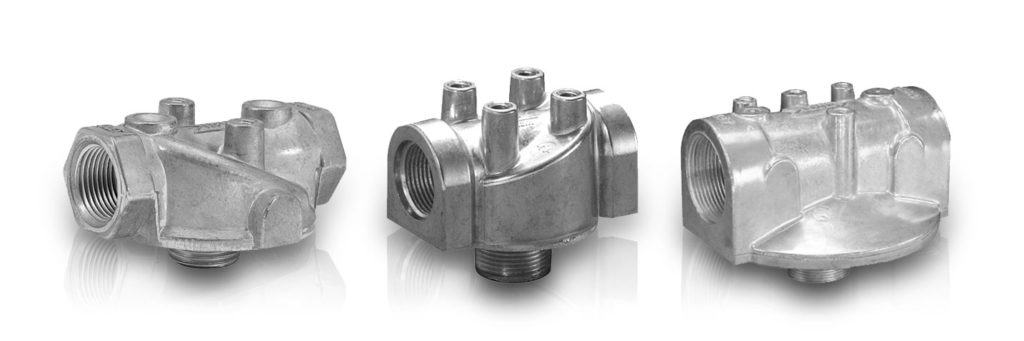

Single Element Spin-On Filter Heads

Designed for most return line applications, Zinga Single-Element Spin-On Filter Heads are compatible with petroleum-based oil in mobile and industrial equipment

Multiple Elements, Parallel Flow Spin-On Filter Heads

For severe, intensified return line flow applications, a variety of configurations, including side-by-side, three-element and four-element filter heads is available

Features and Advantages of Spin-On Filter Heads

Our spin-on filter heads come with a design that prioritizes functionality and durability. Casted in-house using A380 aluminum, Zinga filter heads can withstand hydraulic pressure environments up to 500 PSI without compromising their integrity. The compact structure helps them seamlessly fit into hydraulic systems with limited space. In turn, this allows for efficient filtration without disrupting the flow rates.

Our hydraulic filter heads are compatible with a broad range of spin-on filter elements, which makes it possible to tailor them to specific applications. Performance-wise, our hydraulic spin-on filter elements excel at keeping the oil clean. This is important for preventing abrasive particles from damaging system components and systems.

Cleaner oil also leads to improved operational efficiency. It also reduces the chances of costly downtime due to equipment failure. It’s easy to replace the spin-on filters to minimize any maintenance time while keeping systems running smoothly.

Applications of Hydraulic Filter Heads

Hydraulic filter heads work for diverse applications, from mobile equipment to industrial machinery. In agricultural machines or heavy equipment in construction, hydraulic pumps and actuators are protected from debris that could impact performance levels. For industrial settings, our spin-on filter heads ensure consistent filtration, allowing for precise applications in manufacturing processes.

The adaptability factor allows them to work in systems with varying flow rates and pressure levels. This gives reliable protection in various environments. Our spin-on filter heads are also very durable and versatile, making them a solid choice for anyone wanting to optimize their hydraulic systems. By adding them to equipment, they offer smoother operations, reduce component wear, and enhance the machinery’s lifespan.

Work With Zinga to Get Quality Spin-On Filter Heads

Maximize the efficiency and durability of your hydraulic systems with premium spin-on filter heads. Engineered for performance and reliability, our hydraulic spin-on filter assemblies offer an effective solution for protecting equipment and maintaining clean hydraulic oil. Contact us to learn more about our comprehensive selection and request a quote. Our experts are ready to help you find the right product for your specific needs.

Spin-On Filter Heads Supply with World-Class Service

Another reason our team has an excellent reputation when it comes to providing hydraulic spin-on filter heads is that we provide exceptional customer service:

• Prompt communication: Talk to a real person located at our manufacturing facility within 1-2 business days from the time of your inquiry.

• Five-star service: We go above and beyond to make life easier for purchasing managers, product managers, and production teams.

• Expert solutions: Collectively our team has over 100 years of experience with hydraulic systems and hydraulic filtration.

• Dedication to customer satisfaction: We listen to customers and continue streamlining production and delivery.

• Ongoing support: Our technical support team offers trustworthy troubleshooting assistance for all products.

Looking for a supplier of spin-on filter heads? Contact us to request a quote today!