BE ZBE Series

Spin-On Hydraulic Filter Elements: 3/4-16 Thread, Cellulose & Synthetic Options

FOR USE WITH BF SERIES FILTER HEADS

The BE and ZBE Series spin-on filter elements offer versatile filtration solutions with a compact 3.1-inch OD design and standard 3/4-16 mounting thread. Choose between economical cellulose media (BE Series) for standard applications or high-performance synthetic media (ZBE Series) for extended service life and superior contamination control. Rated for 200 PSI and designed for use with BF filter heads, these elements provide reliable protection for hydraulic systems in industrial and mobile equipment.

Specifications

- Diameter: 3.1”

- Mounting Thread: 3/4” – 16 UN

- Overall Height: 3.4”

- Operating Pressure: 200 PSI Max. Operating

- ∆Pmax Cellulose: 50 PSID without by-pass valve

- Temperature: Up to +250°F Operating

- Applications: Petroleum-based fluids

Applications

- Suction filters

- On the return circuit, for mounting on the line or on the tank cover

- In-line for low and medium pressure applications

- mowers

- tow trucks

- truck-mounted aerial lifts and cranes

- pavers

- compactors

- wood splitters and chippers

- trenchers

- utility terrain vehicles (UTVs).

Specifications

| Part Number | Particle Size | Efficiency (See Below) | Can Color / Imprint | Media Type | Internal By-pass |

| BE100 | 10 Micron | ß9µ(c) = 2 | White / Red | Cellulose | None |

| BE1018 | 10 Micron | ß9µ(c) = 2 | White / Red | Cellulose | 18 PSID |

| BE2525 | 25 Micron | ß17µ(c) = 2 | White / Black | Cellulose | 25 PSID |

| BE400 | 40 Micron | ß22µ(c) = 2 | White / Black | Cellulose | None |

Application Data

- Reference:

- ßXµ(c) = 2 represents 50% efficiency at Particle Size (Nominal Rating)

- ßXµ(c) = 75 represents 98.7% efficiency at Particle Size (Absolute Rating)

- Application: Petroleum-based fluids. Consult factory for synthetic fluids.

- Caution: Do not use BE Series filter elements on internal combustion engines.

Zinga Filter Media Types

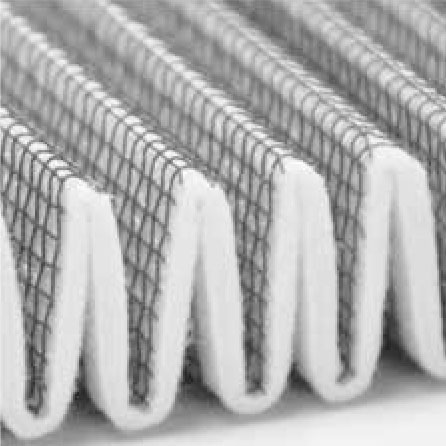

Z-Glass Media

Multi-Layered, non-woven glass media that provides the highest levels of depth filtration efficiency and capacity. Higher capacity means longer service life. Coupled with a steel support mesh, Z-Glass can withstand higher differential pressures.

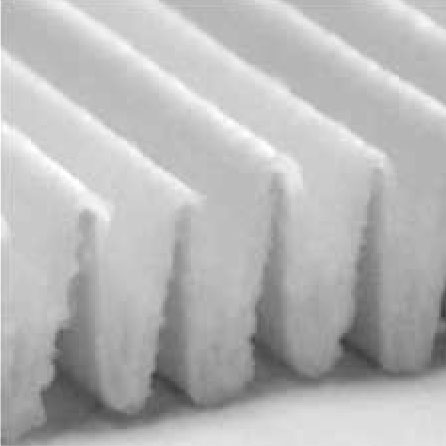

Cellulose Media

Traditional paper based media that provides a nominal level of depth filtration and capacity. Used with petroleum-based fluids only. Some grades of cellulose include a layered glass fiber substrate to provide more efficiency.

AquaZorb Media

Water absorbing cellulose based media designed specifically to absorb and retain free water from petroleum-based fluids. Commonly used in offline systems, AquaZorb will operate until it is fully saturated and ultimately curtail flow through the media. A system by-pass valve and service gauge is recommended when using AquaZorb.

Stainless Steel Mesh

Woven in a variety of precision patterns, stainless steel mesh provides a basic surface type filtration with very low differential pressure. Applications include pump protection and “last chance” valve protection. Stainless steel mesh can be serviced by ultrasonic cleaning. (30: 560µ, 60: 280µ, 100: 141µ, 200:75µ, 200×1400: 10µ)

Compatible Spin-on Filter Heads

BF Series Spin-On Filter Heads

Flows Up To: 7 GPM (Return) 2 GPM (Suction)

Port Sizes: 3/8” NPTF; 9/16”-18 UN (SAE-6)

Pressure: 200 PSI Max.

Temperature: Up to +250°F

Applications: Petroleum-based fluids; consult factory for synthetic fluids